1. Select your testing services

Through our webshop, you will receive your individually marked, production-accompanying samples as STL files. Your individual production documentation and your shipping documents for our logistics service provider will also be included.

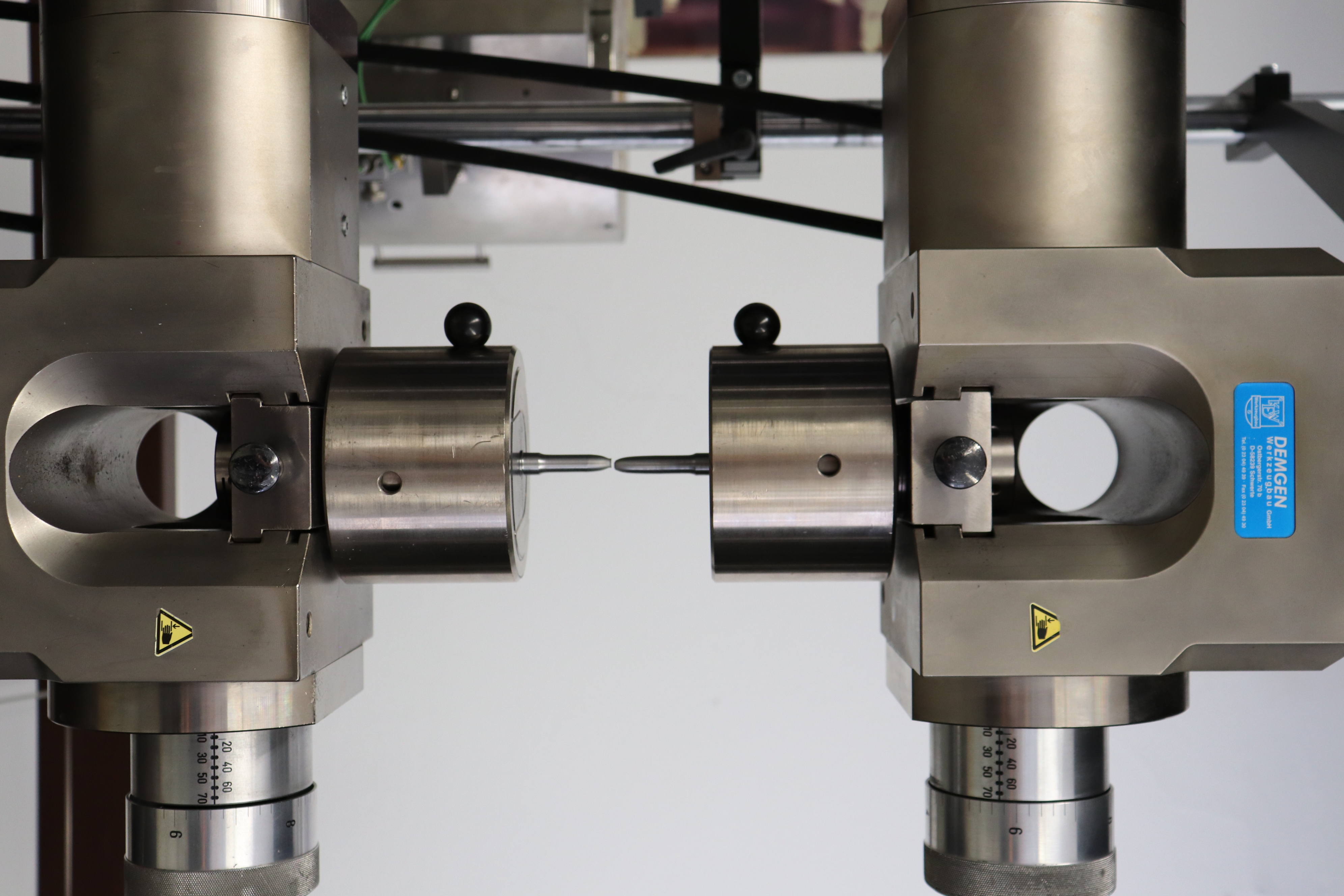

2. Print your test specimens

Simply add the production accompanying-samples provided to the build job for inspection and then send them to the lab - free of charge - using the shipping label provided.

3. Receive your TÜV NORD proof of quality

Simply add the production accompanying-samples provided to the build job for inspection and then send them to the lab - free of charge - using the shipping label provided.