Preparation for certification of industrial AM manufacturing facilities according to DIN EN ISO / ASTM 52920

Our services

Filter

We offer you as required

- the complete testing service

- retainment of your specimens

How does the testing process work?

-

Choose the test

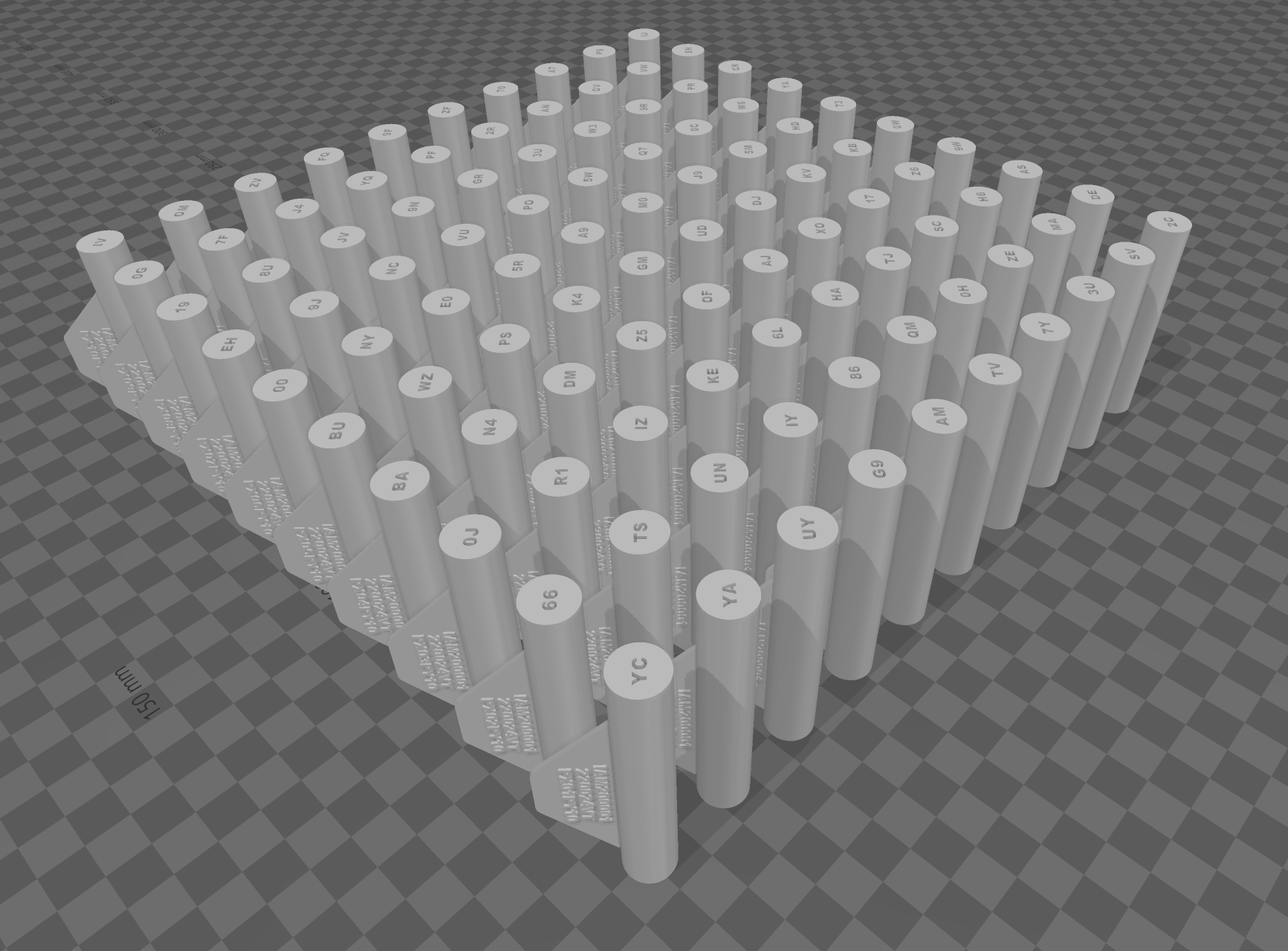

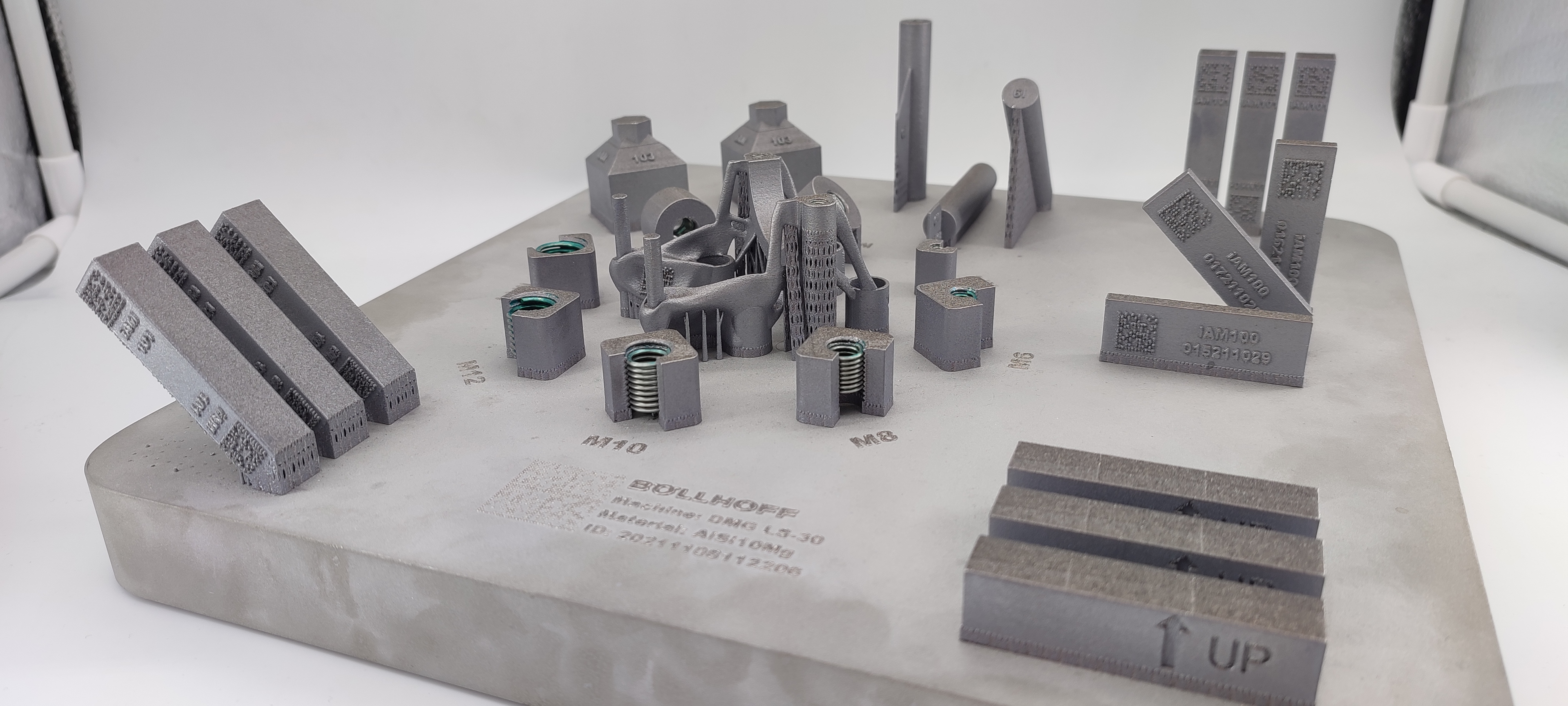

Choose the matching material for your machine (metal or polymers). Depending on the size of your build space and desired test density, you will receive a digital print job with tensile specimens in STL format. - Start the build job

You receive a digital build job with tensile specimens arranged in a grid. Start the build job under your desired conditions. - Send them in

Send all the specimens from the build job to the TÜV NORD using the shipping label provided. The specimens are tested in an accredited laboratory and a build space distribution is created based on the mechanical-technological properties (“heat map”). - Receive proof

You receive a report that shows which mechanical-technological properties were achieved at which position in the build chamber.

Machine capability tests

Building-chamber:

250x250

|

Job Density:

High (10x10)

The machine capability test is a useful component in the preparation for the certification of industrial additive manufacturing facilities according to DIN EN ISO / ASTM 52920. In the machine capability test, the spatial distribution of the actually achievable mechanical-technological properties within the machine build space is determined. For this purpose, the installation space is divided by a grid into segments, in each of which a test specimen is to be manufactured. The results of the tensile tests allow these properties to be analyzed and assigned to the individual segments of the build envelope. For visualization purposes, a heat map can be created that shows in color whether predefined limit values have been reached or not. Based on this, the machine can be adjusted.

Important parameters for the initial verification as well as the ongoing control of the industrial machine capability are the mechanical-technological properties according to DIN EN ISO 6892-1: Determination of the 0.2% yield stress Rp 0. 2 [MPa] Determination of the 1% yield stress Rp 1.0 [MPa] Determination of the tensile strength Rm [MPa] (for austenitic materials)Determination of the elongation at fracture Ac [%] Determination of the fracture position Young's modulus [GPa] Included Services Provision of a segmented construction job with the desired number of segments and corresponding test specimens for your build spaceTest specimen certificate and instructions Shipping label incl. pick-up and shipping tracking Execution of the tensile tests in an accredited laboratory Test report from TÜV NORD as PDF Heatmap to visualize the distribution of the test results within the build space (see example image) For other options e.g. further individual build space configurations please contact us.

Building-chamber:

250x250

|

Job Density:

Low (4x4)

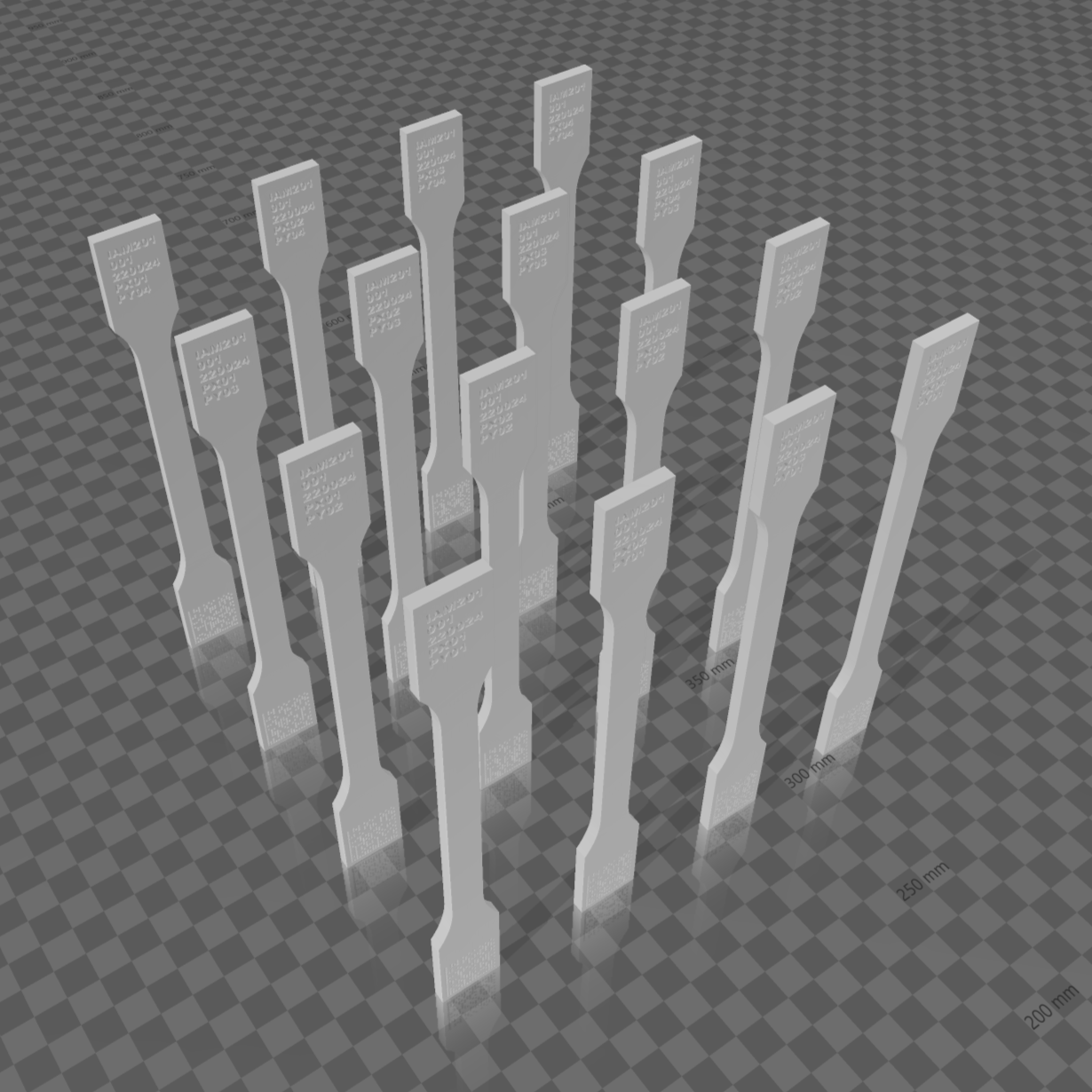

The machine capability test is a useful component in the preparation for the certification of industrial additive manufacturing facilities according to DIN EN ISO / ASTM 52920. In the machine capability test, the spatial distribution of the actually achievable mechanical-technological properties within the machine build space is determined. For this purpose, the installation space is divided by a grid into segments, in each of which a test specimen is to be manufactured. The results of the tensile tests allow these properties to be analyzed and assigned to the individual segments of the build envelope. For visualization purposes, a heat map can be created that shows in color whether predefined limit values have been reached or not. Based on this, the machine can be adjusted. Important parameters for the initial verification as well as the ongoing control of the industrial machine capability are the mechanical-technological properties according to DIN EN ISO 527-1:2019-12:Determination of the stress-strain diagram Determination of the strength σm [MPa]

Determination of the strain at break εb [%]

Indication of the fracture position

E-modulus [GPa]

Test performance at room temperature.

Included Services Provision of a segmented construction job with the desired number of segments and corresponding test specimens for your build space

#+Test specimen certificate and instructions Shipping label incl. pick-up and shipping tracking Execution of the tensile tests in an accredited laboratory Test report from TÜV NORD as PDF Heatmap to visualize the distribution of the test results within the build space (see example image)For other options and special requests please contact us.

How does the testing process work?

-

Choose the test

Choose the matching material for your machine (metal or polymers). Depending on the size of your build space and desired test density, you will receive a digital print job with tensile specimens in STL format. - Start the build job

You receive a digital build job with tensile specimens arranged in a grid. Start the build job under your desired conditions. - Send them in

Send all the specimens from the build job to the TÜV NORD using the shipping label provided. The specimens are tested in an accredited laboratory and a build space distribution is created based on the mechanical-technological properties (“heat map”). - Receive proof

You receive a report that shows which mechanical-technological properties were achieved at which position in the build chamber.