Price by request

.JPG) |

|

Dipl.-Ing. Jens Groffmann |

|---|

- Determination of the stress-strain diagram

- Determination of the strength σm [MPa]

- Determination of the strain at break εb [%]

- Indication of the fracture position

- E-modulus [GPa]

- Test performance at room temperature.

Included Services

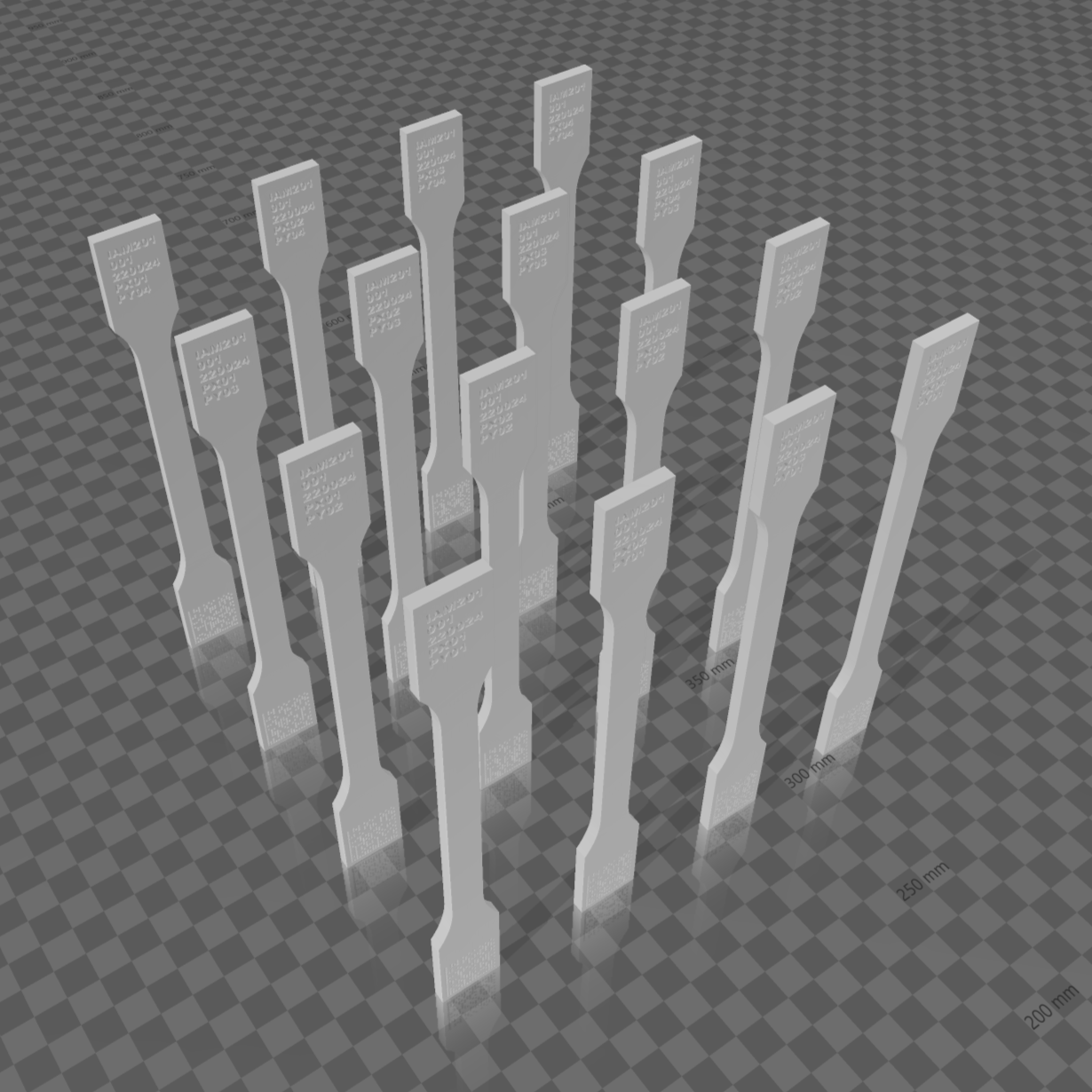

- Provision of a segmented construction job with the desired number of segments and corresponding test specimens for your build space #+

- Test specimen certificate and instructi

- ons Shipping label incl. pick-up and shipping tracking

- Execution of the tensile tests in an accredited laboratory

- Test report from TÜV NORD as PDF

- Heatmap to visualize the distribution of the test results within the build space (see example image)

.JPG) |

|

If you have any questions about additive manufacturing and corresponding TÜV NORD testing services, please do not hesitate to contact Jens Groffmann at any time: Dipl.-Ing. Jens Groffmann |

|---|