Product information "Powder testing - Metal DIN EN ISO ASTM 52907-01"

- The test results serve as a necessary basis for drawing conclusions about the causes of deviations in the component properties

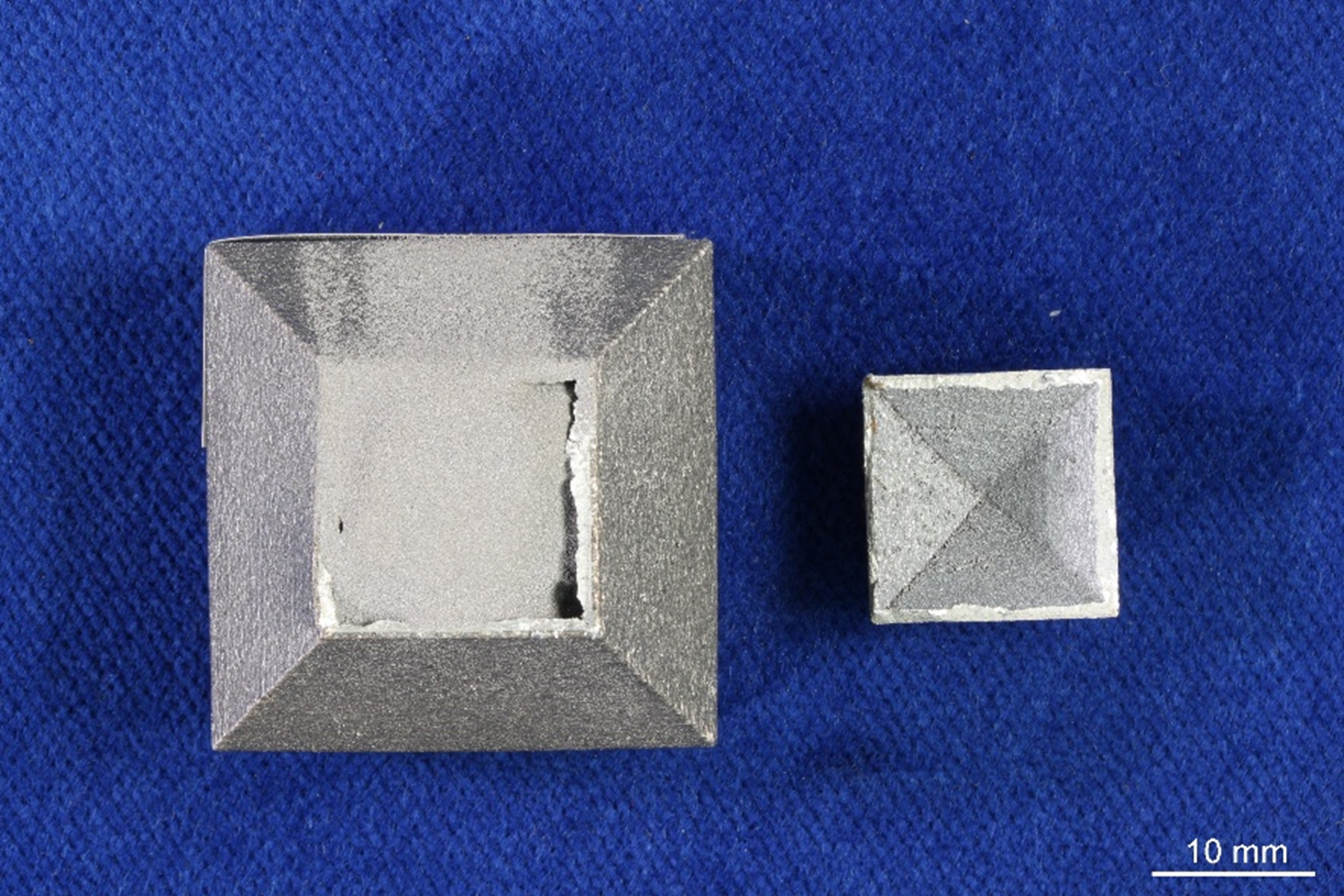

- The container must be printed in the respective build order at the same time and under the same conditions as the actual part

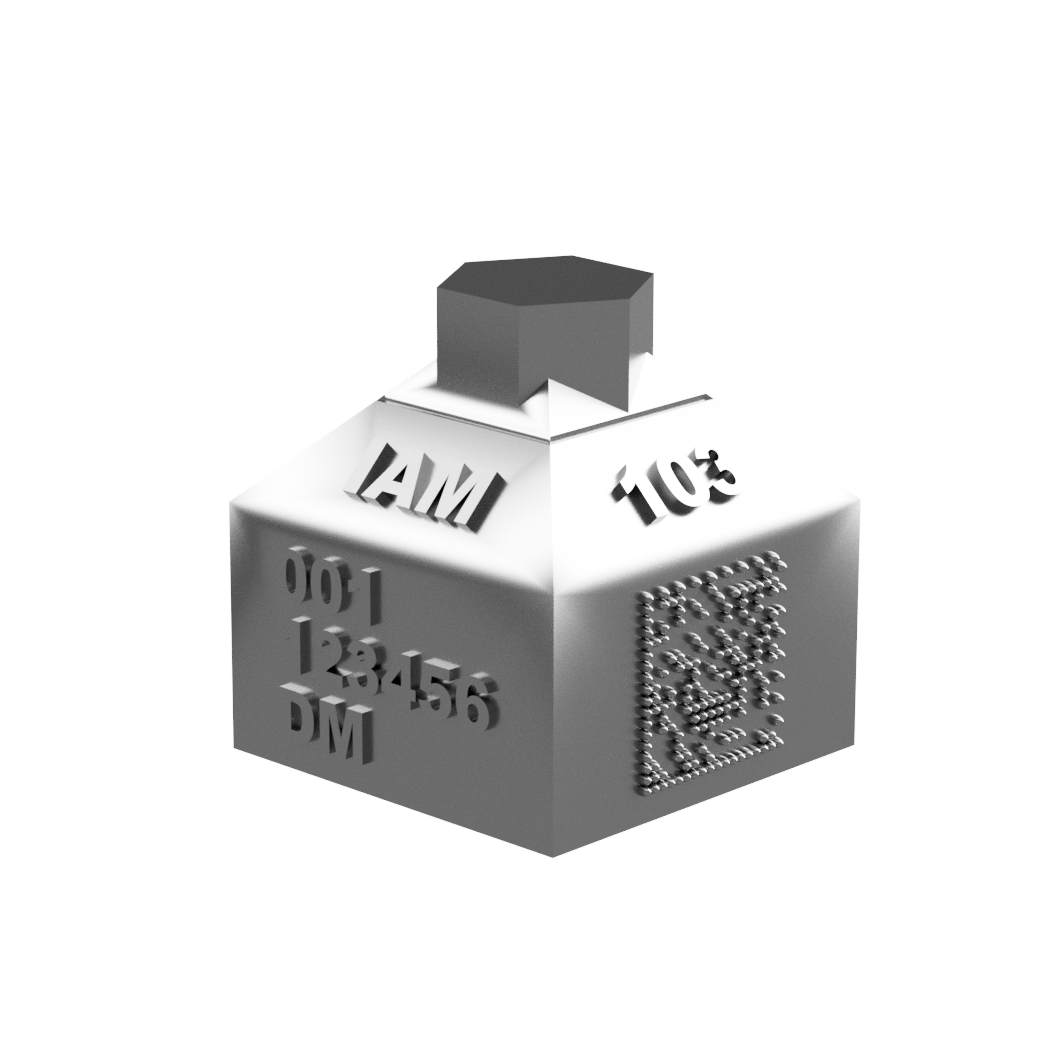

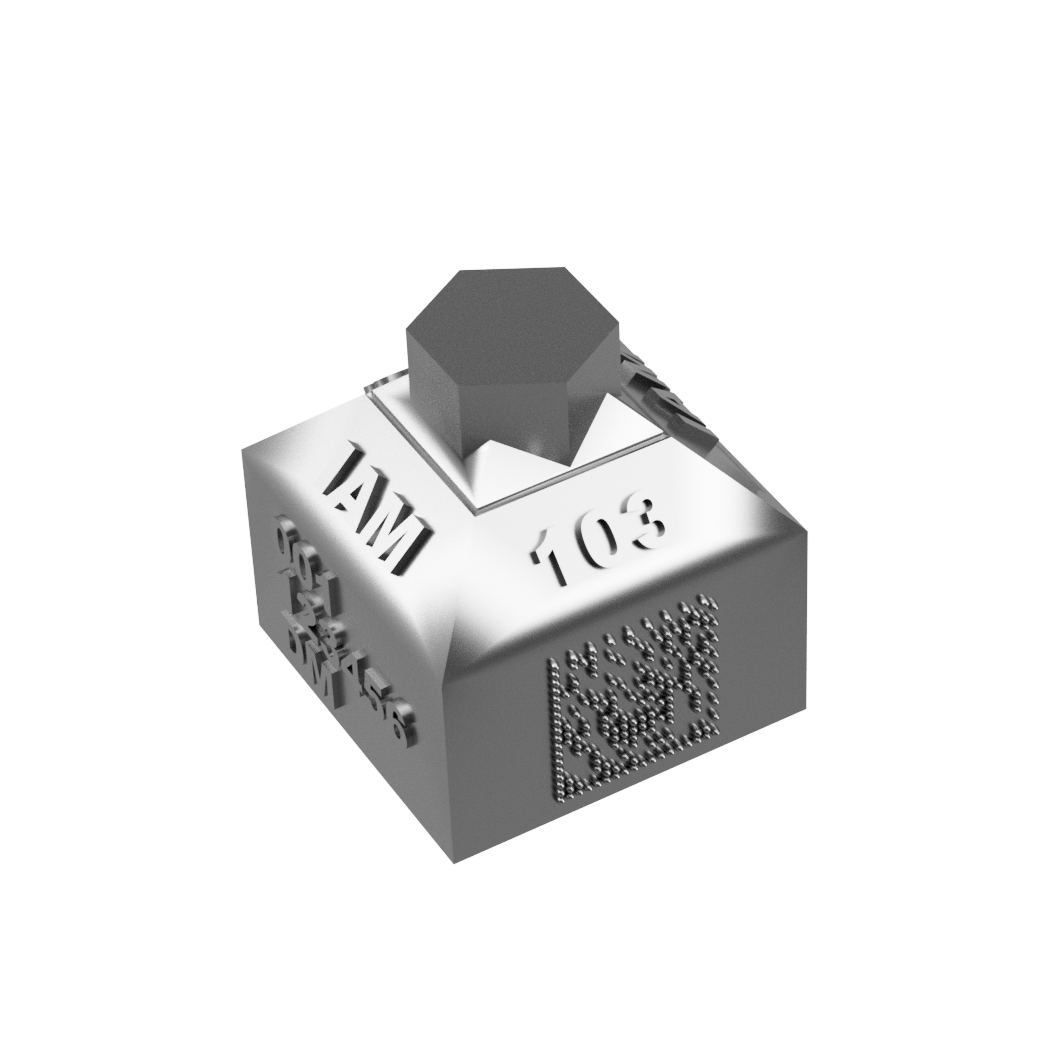

- TÜV NORD sampling container for AM powder materials is delivered to the customer digitally as an STL file, the test results are provided digitally as a PDF

- Unique identification: Each container can be assigned to a customer/construction order via a unique number and a machine-readable data matrix code

- Due to the printed identification, mix-ups are practically impossible. The handling effort on the customer's side and in the laboratory is considerably reduced

- If required, we test the powder composition of the powder mixture actually used during the build job according to DIN EN ISO ASTM 52907-01.

- Particle–size Distribution

- Morphology

- Chemical Composition

- Density: Bulk Density, Tap Density

- Flowability

- Degree of Purity

Depending on the material and machine, different tests are carried out to ensure the quality of the powder. The prices and testing possibilities are therefore to be inquired. Please contact our expert Mr. Groffman or use the form below:

.JPG) |

|

Dipl.-Ing. Jens Groffmann |

|---|