Product number:

iAM108.8

PDF offer

Create PDF offer for this product

Tip: Add multiple products to the cart and create the offer there. Logged in users get an individualized offer.

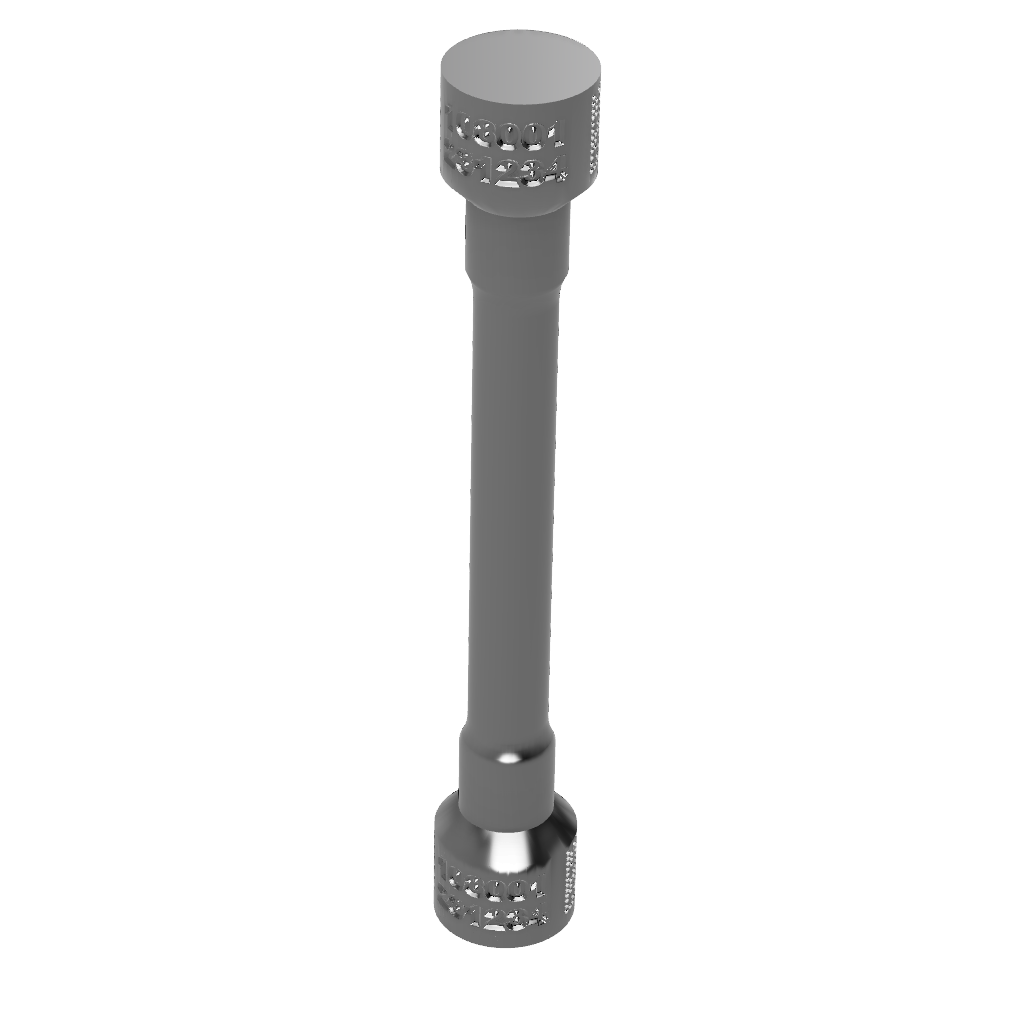

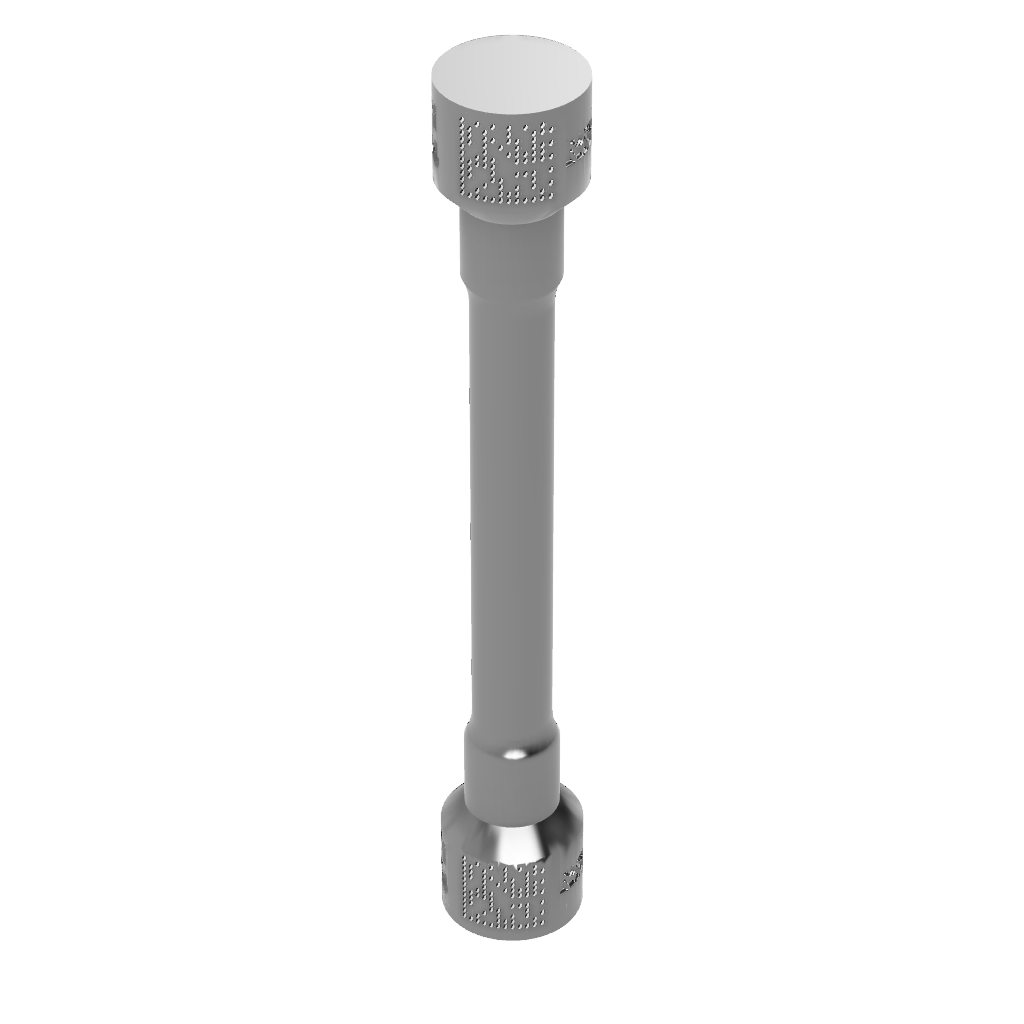

Product information "Tensile Test - Ø10mm based on DIN EN ISO 6892-1 as built (no surface processing)"

This test determines the mechanical-technological properties of the accompanying sample with an unmaschined surface as proof for you or for your customer. As a result surface influences are represented in the test results.

This test specimen is an as-build specimen. It is not maschined before testing.

This test specimen is an as-build specimen. It is not maschined before testing.

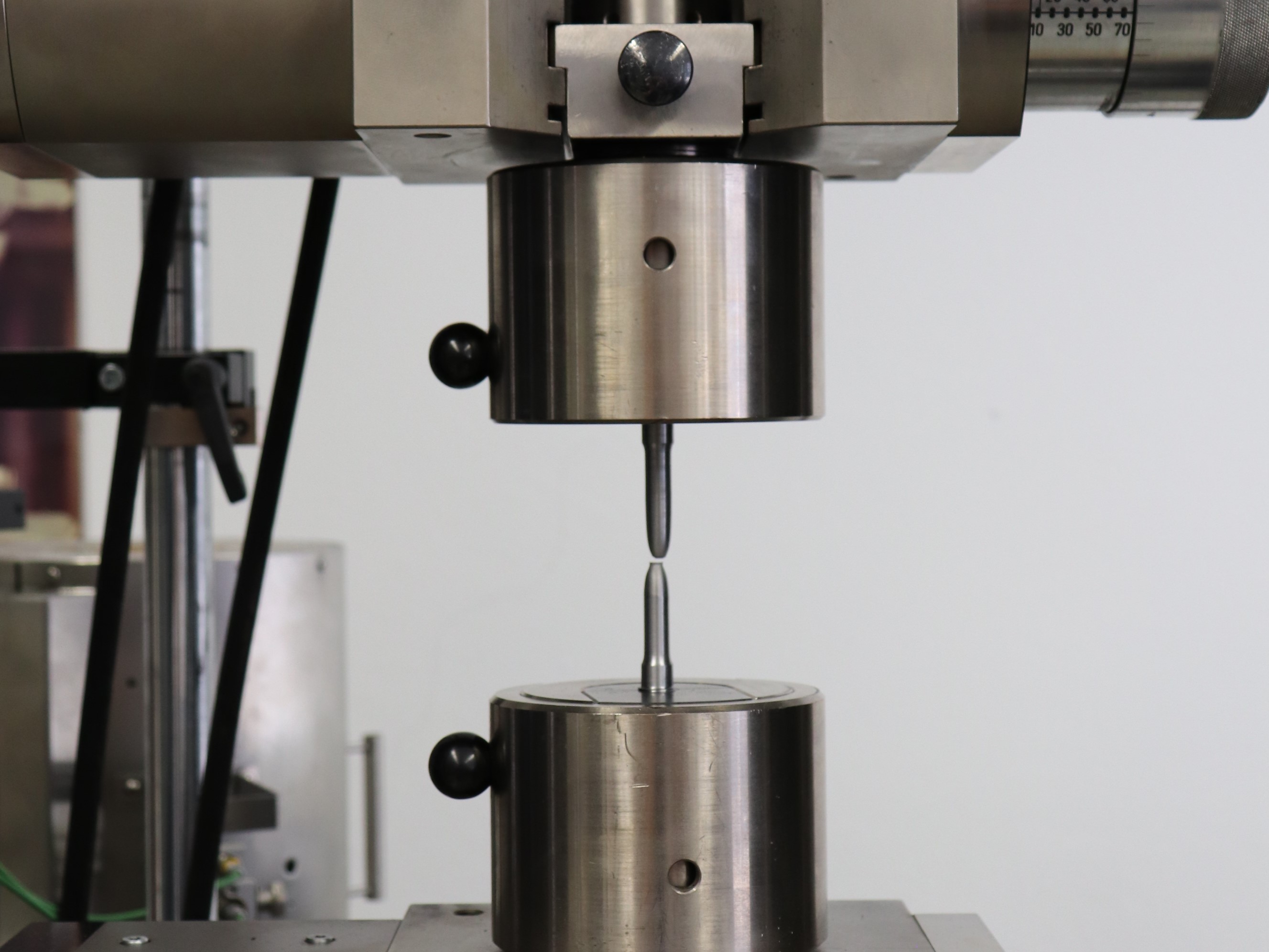

- Proof of the achieved mechanical-technological properties based on DIN EN ISO 6892-1

- Determination of the 0.2% yield strength Rp0.2 [MPa]

- If necessary, determination of the 1% yield stress Rp1.0 [MPa] for austenitic materials

- Determination of the tensile strength Rm[MPa]

- Determination of the elongation at fracture Ac [%]

- Determination of the percentage reduction of area [%]

- Indication of the fracture position

- Test performance at room temperature. (Higher temperatures according to DIN EN ISO 6892-2 possible on request).

- Summary of test results in a TÜV NORD test report

Included Services

- Provision of a digital accompanying sample (individualized STL file)

- Test specimen accompanying certificate and instructions

- Shipping label incl. Collection and shipment tracking

- Mechanical production of the standard-compliant test specimen from the production accompanying sample

- Test execution

- TÜV NORD test report as PDF

For other options and special requests please contact us.

The HTV corporate group represents extensive technological competence, the highest possible quality standards and over three decades of experience in regards to providing services for electronic components. State of the art machinery, continuously growing and being adapted to the ever rising challenges of material testing and analyses, as well as teams consisting of over 150 engineers, scientists, technicians and specialists allows us to gain detailed insight into every aspect of electronic components, even down to the deepest level of construction. HTV stands for creativity, success and vision, coupled with performance, courage, optimism and fairnes. Traditional values such as honor, decency and trust form the basis for this. Highest quality and top performance as well as optimal customer care and service are further fundamental values that are firmly anchored in the entrepreneurial thinking of all HTV employees. The definition and continuous monitoring of quality targets and ongoing process improvement are mandatory.

As AM processes are seeing more and more usage in sensitive and critical to security areas, such as medical technologies and the aerospatial industry, quality ensuring processes are becoming similarly important. A precise analysis, should damage come to pass, is more often than not the best way to improve product reliability or to better understand the processes involved. This makes having a powerful and efficient partner, who supports manufacturers of 3D-printed components with the best possible support in terms of

analytical expertise, all the more important. The HTV Conservation GmbH’s Institute

of Material Analysis provides every supplier of additively manufactured components with a full spectrum of analytics to ensure the best possible quality, as well as full support in terms of optimizing the manufacturing processes.

Contact for testing services:

Dr. -Ing. Thorsten Leist

Analytics Expert HTV Conservation GmbH

Robert-Bosch-Straße 28

D-64625 Bensheim

Tel.: +49-6251-84800-0

E-Mail: leist[at]htv-conservation.com

Analytics Expert HTV Conservation GmbH

Robert-Bosch-Straße 28

D-64625 Bensheim

Tel.: +49-6251-84800-0

E-Mail: leist[at]htv-conservation.com

Prices and options

TÜV NORD GROUP stands for safety. For decades, our employees have ensured that knowledge, independence, and the highest quality are associated with us. We have accompanied all industrial revolutions, helped develop globally recognized safety standards, and contribute to a safe world. Now, digitalization, global networking, and ever shorter product cycles are placing new, additional demands on us. We want to know exactly what our customers need from us for their success. For precisely tailored, digital services, we are strengthening contact with customers and intensifying cooperation between all business units.

We want our customers to succeed.

We want our customers to succeed.

.JPG) |

|

If you have any questions about additive manufacturing and corresponding TÜV NORD testing services, please do not hesitate to contact Jens Groffmann at any time: Dipl.-Ing. Jens Groffmann |

|---|