Have your build jobs checked for quality!

Our services

- the complete testing service

- retainment of your specimens

How does the testing process work?

-

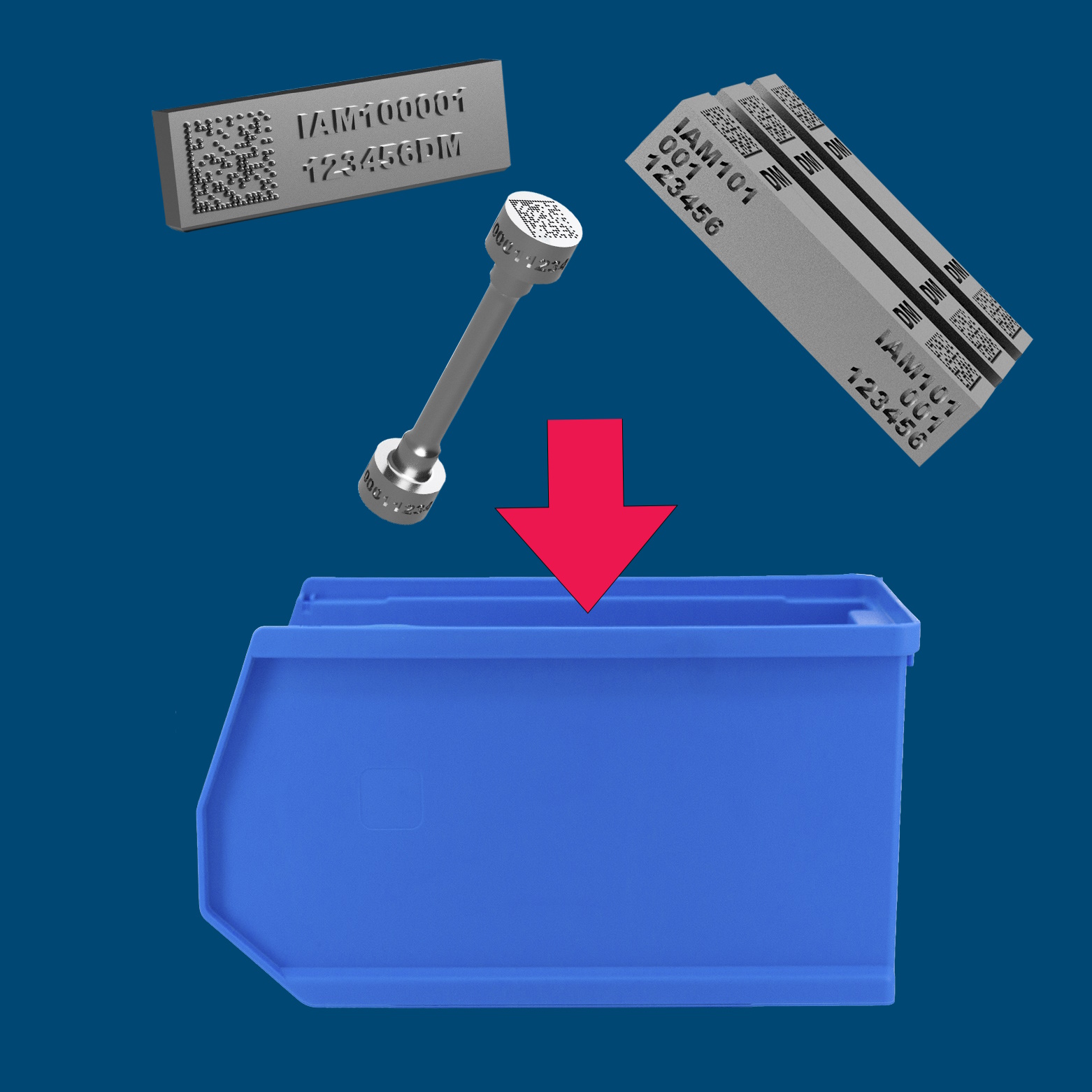

Choose the test

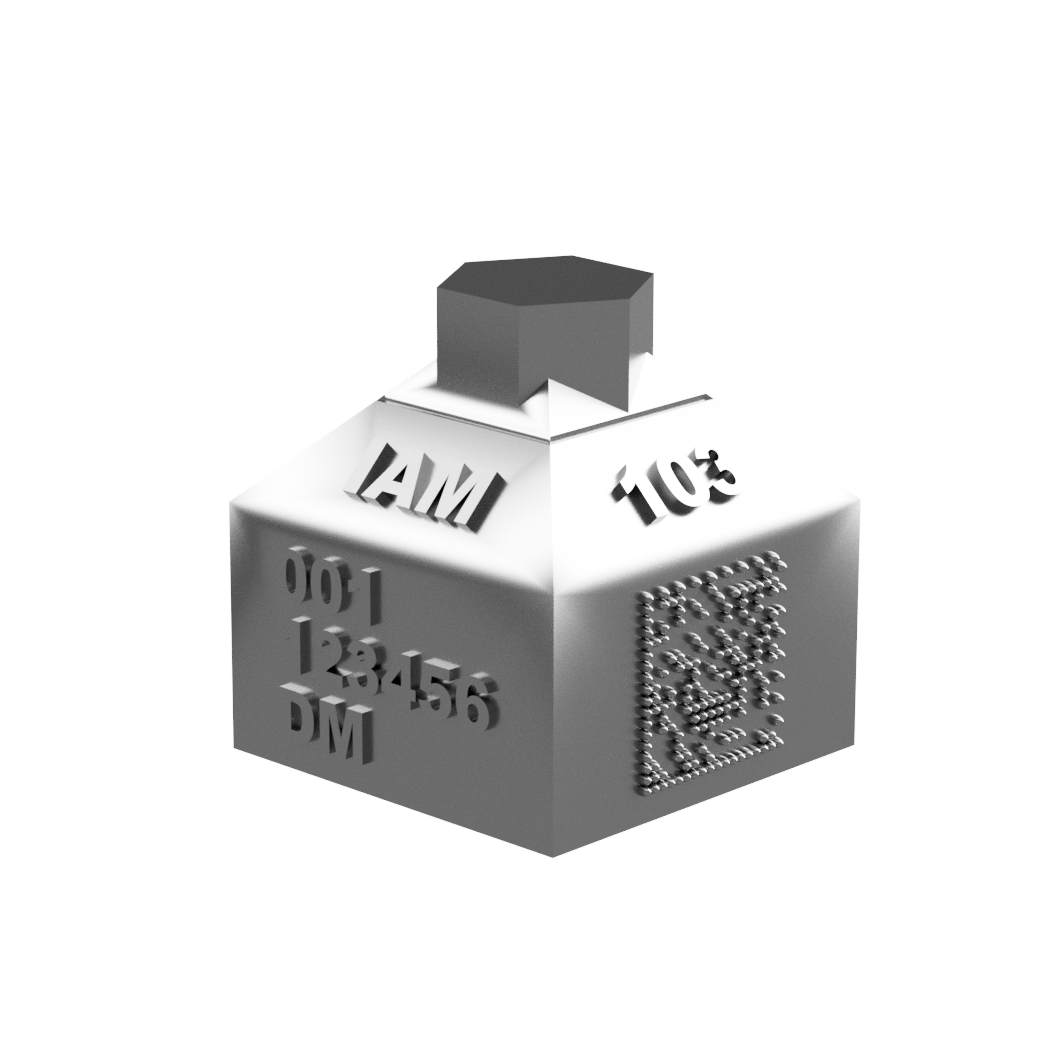

Choose the specimen required for the test you want to have performed. Click on “Details” to configurate your test. - Build your specimen

You receive the specimens digitally. Put them next to your parts in the build job you would like to check and print them. - Send them in

Send the specimen to TÜV NORD using the included shipping label. The requested tests are performed in an accredited laboratory. - Receive proof

You will receive a certificate with all the values determined in the test. This provides the basis from which conclusions can be drawn about the build job.

Our testing services for metal

How does the testing process work?

-

Choose the test

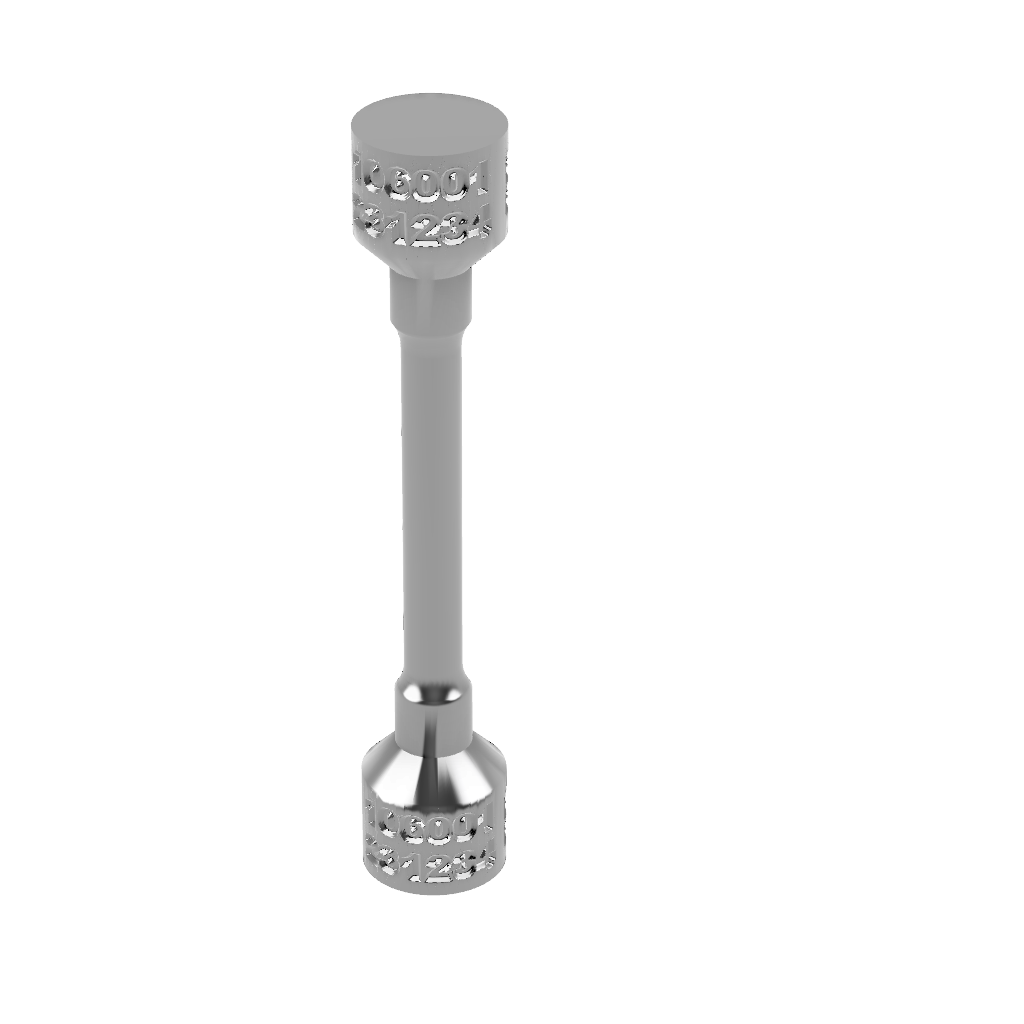

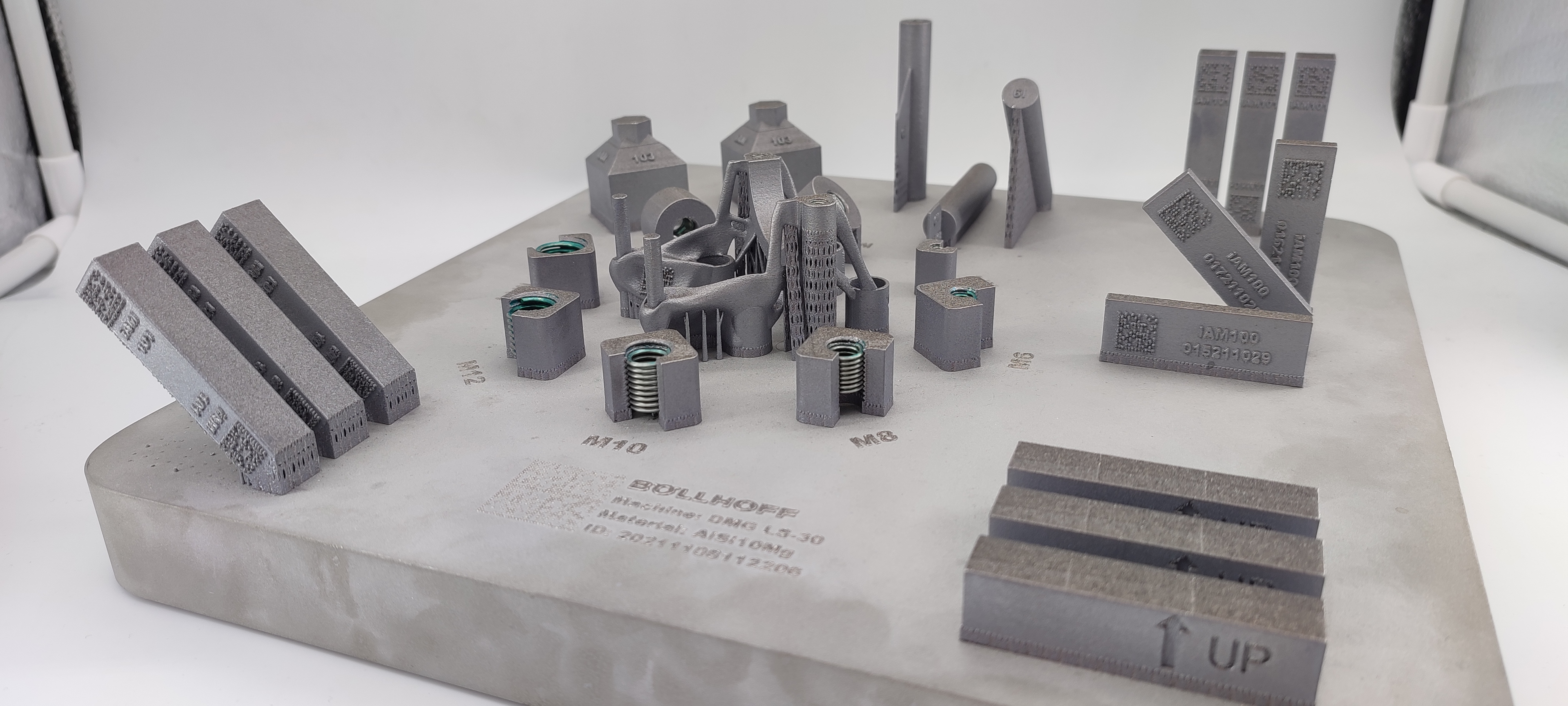

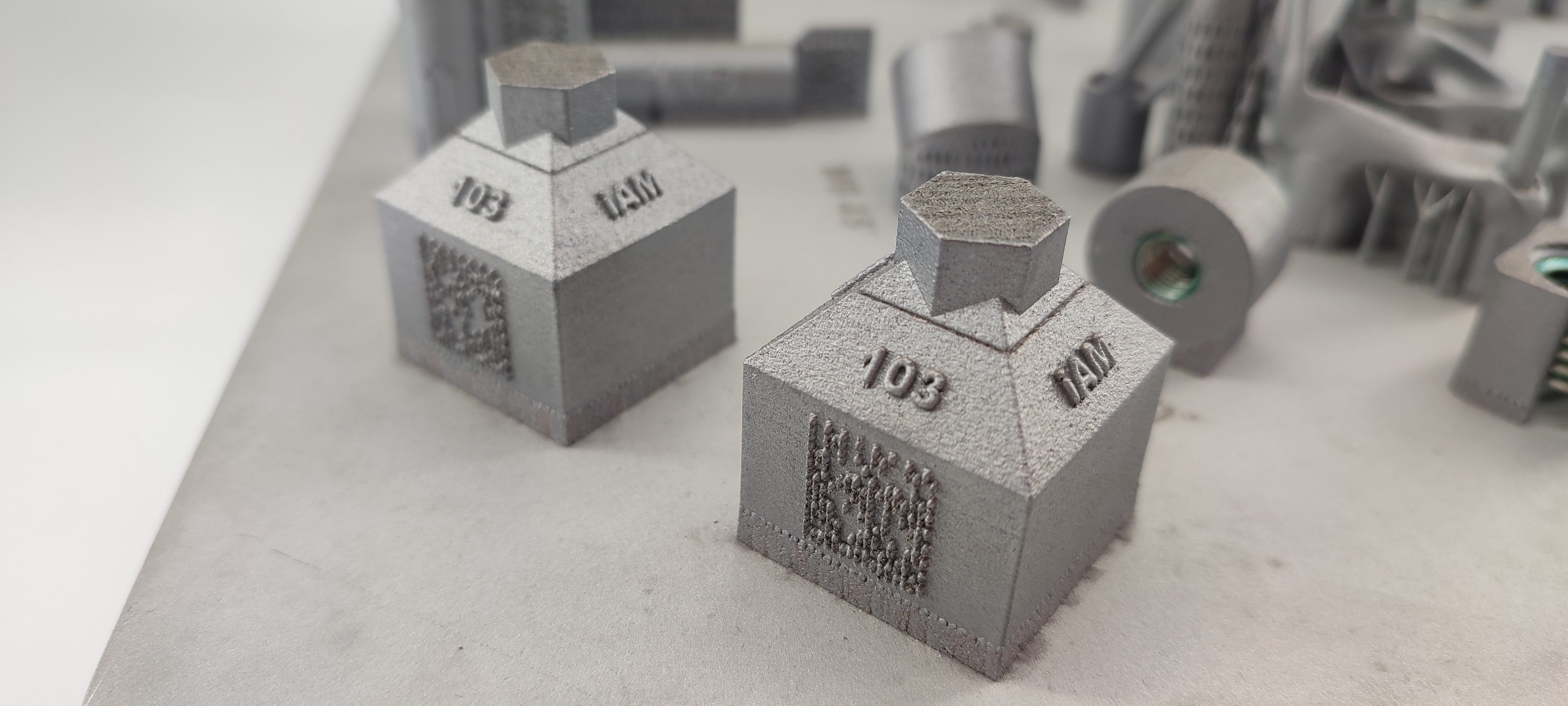

Choose the specimen required for the test you want to have performed. Click on “Details” to configurate your test. - Build your specimen

You receive the specimens digitally. Put them next to your parts in the build job you would like to check and print them. - Send them in

Send the specimen to TÜV NORD using the included shipping label. The requested tests are performed in an accredited laboratory. - Receive proof

You will receive a certificate with all the values determined in the test. This provides the basis from which conclusions can be drawn about the build job.

How does the testing process work?

-

Choose the test

Choose the specimen required for the test you want to have performed. Click on “Details” to configurate your test. - Build your specimen

You receive the specimens digitally. Put them next to your parts in the build job you would like to check and print them. - Send them in

Send the specimen to TÜV NORD using the included shipping label. The requested tests are performed in an accredited laboratory. - Receive proof

You will receive a certificate with all the values determined in the test. This provides the basis from which conclusions can be drawn about the build job.